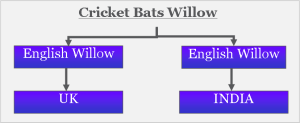

Cricket Bats are manufactured from a wood (English or Kashmiri Willow). During bat manufacturing ,different process in sequence takes place in order to get the perfect cricket bat. Willow selection for cricket bats is an important aspect during bat manufacturing. English Willow is best in class willow for bat and no doubt it is first preference of all bat manufacturers around the globe.

English willow is the finest type of willow because it give high performance and durability during critical batting condition. Kashmiri willow is the substitute of english willow and mostly available in kashmir valley of India. This type of willow is bit harder as compare to English Willow.Cricket bat with this type of willow is suitable for entry or average level of cricket players.

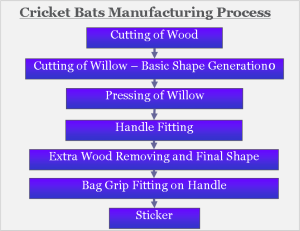

Now let us discuss the cricket bat manufacturing process . Bat manufacturing process is totally a manual skilled job and the perfect shape and size of bats is totally depends on skill level of operator.Few companies like GM Cricket, also used state of art Computer Added Manufacturing technique which give fine accuracy and surface finish as compared to manual job.

Cutting Process :

In this Process , trees are cut into standard size logs which further cuts into defined shape wadge known as clefts. To manufacture standard bat , clefts should be defect free , should contain perfect fibers shapes and moreover the perfect moisture contents. Carefully selected clefts are then placed into drying room to remove the moisture .Normally it takes 6 month to achieve the desire condition on wood for further processing.Once the clefts are dried as per requirement , further it cuts into shape of the bat. Manufactures also give the shape of handle and toe .At this point of time it is also important to finalize the best end of bad which could give the super performance.

Pressing Process :

With Pressing operation , bat internal fibers come closer and provide strength so that bat can withstand the impact caused by cricket ball.Pressing is an important operation as over pressing can make bat surface hard.So it is desirable to do this operation carefully with skill hand or machine.

Handle Fitting:

After Pressing operation , Next operation is to fit the handle to cricket bat. Handle in normally prepared with cane laminated with rubber strips which gives flexibility and improve the strength of handle. Handle is placed into cricket bat wadge with adhesive material so that handle can make joint with bat. Both handle and bad, further pressed in vice to give desired shape.

Shaping Operation :

After Fitting the handle , wood craftsman place the bat into vice and give the final shape of cricket bat by removing the extra wood with the help of tool known as Draw Knife. In this operation cricket bats performance and its playing style is decided as craftsman as per bat specification changes the bat meat position. By changing the quantity and position of meat , bat performance can be changed.

Final Finishing:

Further , Cricket Bat is sanded , shoulder of bad gets its shape , grip of handle place into bat. Final finishing of Cricket Bats takes place with the help of horse's shin bone. Manufacturer logo are added into Bat. Now your bat ready to play. But please don't forgot the knock In and Oiling of Cricket Bats.

So this is the complete sequence of Cricket Bat Manufacturing process. In India Meerut , U.P - is the hub of Cricket Bat manufacturing and word well known companies like SS, SG , BDM , Kookaburra , SF , SM Pinto are manufacturing cricket equipment form here.

To Visit Full Range of Cricket Bats please visit www.khelmart.com